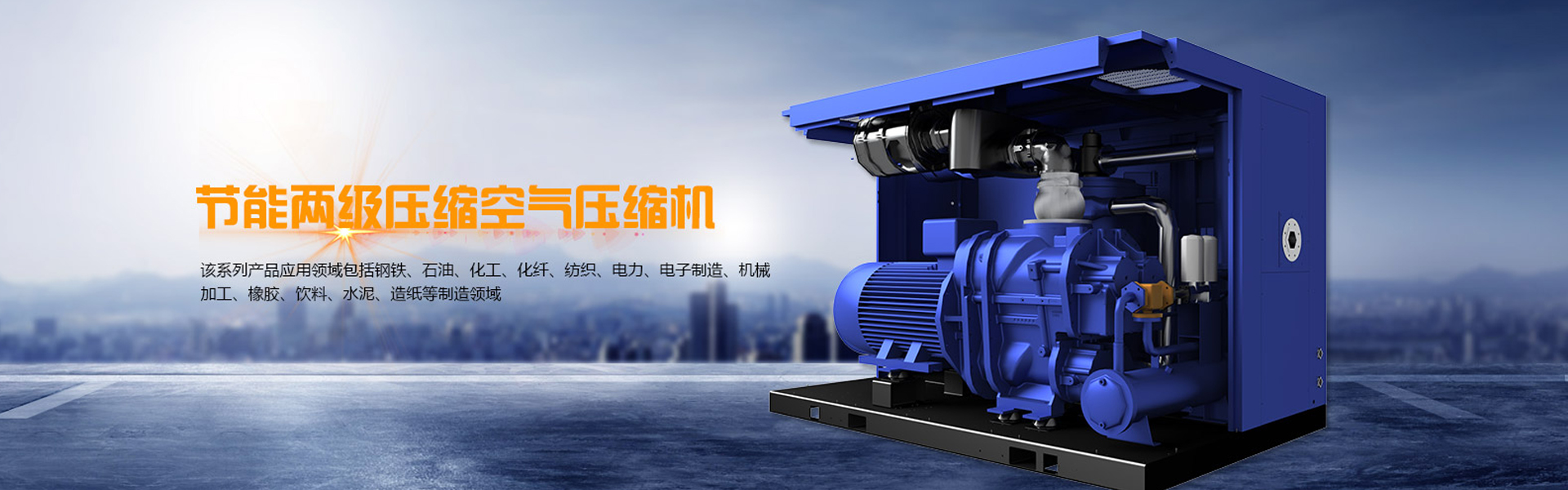

根据工程热力学理论,空压机在压缩过程中等温压缩最省功。(温度高的时候气体的密度越低,压缩需要用的功就多)。不仅如此,等温压缩不但可以减少消耗的功,还能降低压缩后气体的温度,使空压机材料的使用更为宽广和经济,使空压机的运行更为可靠。但是等温压缩,就要使气体热量随时与外界交换,气体温度与外界相等,在实际工作中是不可能实现的。而通过分级压缩加中间冷却是降低排气温度的有效方法。

According to the theory of engineering thermodynamics, the isothermal

compression of the air compressor saves the most work in the compression

process. (when the temperature is high, the lower the density of the

gas, the more work is needed for compression). Moreover, isothermal

compression can not only reduce the work consumed, but also reduce the

temperature of the compressed gas, make the use of air compressor

materials more broad and economical, and make the operation of air

compressor more reliable. However, isothermal compression requires the

gas heat to be exchanged with the outside world at any time, and the gas

temperature is equal to the outside world, which is impossible to

achieve in practical work. Staged compression plus intermediate cooling

is an effective method to reduce the exhaust temperature.

另外,两对转子同时做功,打气速度快,出气量大,这点是单级无可替代的优势。而且由于双级压缩,每级的压缩比较单极压缩要小很多,转子和轴承受到的压力小,再加上转子直径大、转速低,所以运行更可靠。

In addition, two pairs of rotors work at the same time, with fast air

pumping speed and large air output, which is an irreplaceable advantage

of single stage. Moreover, due to the two-stage compression, the

compression of each stage is much smaller than that of unipolar

compression, and the pressure on the rotor and bearing is small. In

addition, the rotor diameter is large and the speed is low, so the

operation is more reliable.